HOME > MELT PRESSURE > TERWIN > MELT PRESSURE MEASUREMENT & CONTROL

TERWIN TESTING SYSTEMS

TERWIN 2000 SERIES

Environmentally Friendly

What It's For

In 1983 Terwin introduced the patented 2000 Series "High Temperature / Environmentally Friendly" extrusion melt pressure transducer. This safe, accurate, and competitively priced transducer incorporates a unique mechanical design to overcome the problems of large zero and span shifts caused by changes in process temperatures.

Download More :

Handling Procedures

Advantages of Using The Terwin 2000 Series

YOU MAY ALSO LIKE

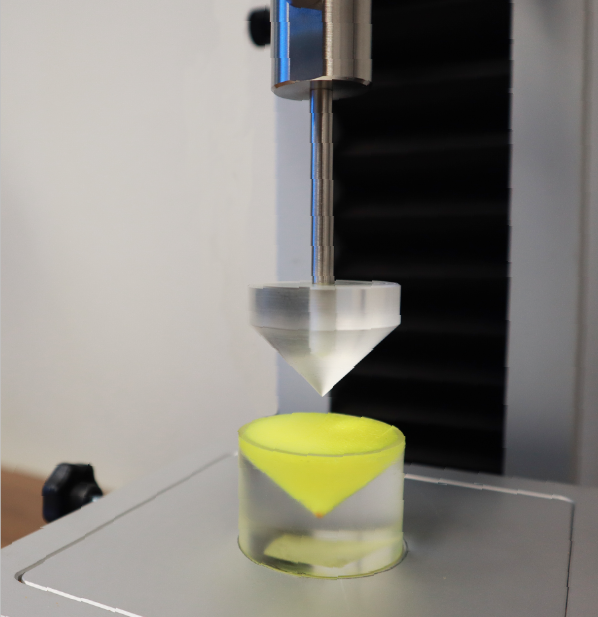

Texture Analyzer

BRAVO Food Texture Analyzer : TA Prime

เครื่องทดสอบลักษณะเนื้อสัมผัสของอาหาร

Leak Test Chamber

BRAVO Leak Test Chamber : SQ Series

เครื่องทดสอบรอยรั่วของบรรจุภัณฑ์

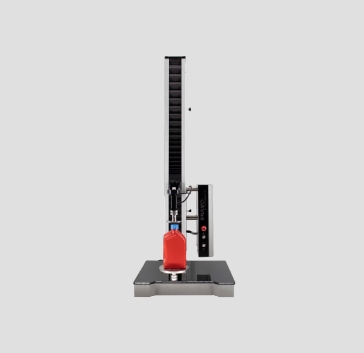

Tensile Tester

BRAVO Universal Testing Machine MS Pro

เครื่องทดสอบแรงดึง-กดแบบเสาเดี่ยว

Texture Analyzer

BRAVO Food Texture Analyzer : TA Pro

เครื่องทดสอบลักษณะเนื้อสัมผัสของอาหาร